At a small roundtable session with AMD executives at CES 2025 in Las Vegas, we asked the company for details about continuing shortages of its flagship gaming-optimized Ryzen 7 9800X3D — currently the uncontested best CPU for gaming — and when we can expect the supply to improve. AMD chalked it up to unprecedented demand and noted that Intel's "horrible" product, also known as Arrow Lake, has led to wildly increased demand that has pushed far beyond initial projections. In a separate roundtable, I also had the chance to ask Intel about its plans to fire back at AMD's dominating 3D V-Cache processors.

"We knew we built a great part. We didn't know the competitor [Intel] had built a horrible one," quipped AMD executive Frank Azor. "So the demand has been a little higher than we forecasted."

It's no secret that Intel's Arrow Lake delivered underwhelming gaming performance at launch. Although the company has promised a 'fix' for the issue, we recently tested the full and complete patch on multiple systems. We found the patch does nothing to help (at least on two motherboards) and that the newer Windows revision required for the fix has benefited competing processors more, thus making Intel's Arrow Lake competitive positioning even worse than at launch. We'll publish that testing soon.

All of this means that Intel is far less competitive than AMD anticipated. That's exacerbated the longer-than-normal lead time for building an X3D processor. Due to the long lead times associated with building modern high-end processors, forecasting demand is key. Now that demand has far outstripped the original production targets, the company is cranking higher production into gear— but that takes time to filter down to the retail market.

"We have been ramping our manufacturing capacity, or the monthly, quarterly output of X3D parts, period, and that's 7000 [series] as well as 9000X3D," said AMD executive David McAfee. "It's crazy how much we have increased over what we were planning. I would say the demand we've seen for the 9800X3D and the 7800X3D has been unprecedented. So the demand has been higher than ever."

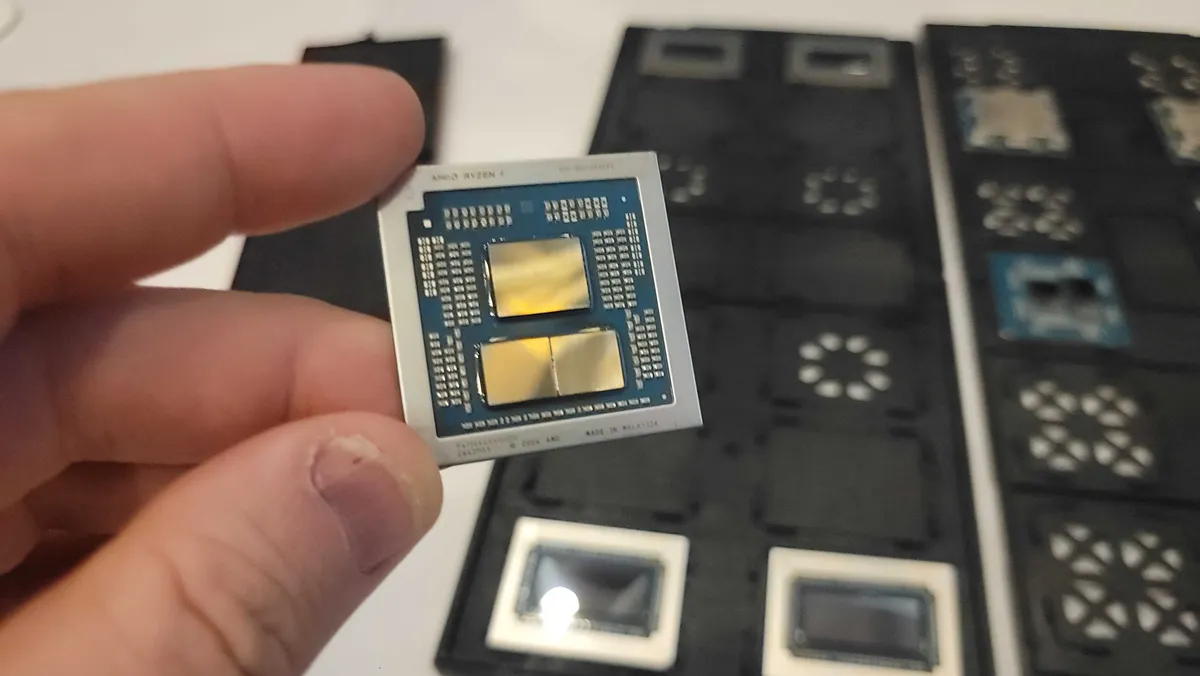

"Building a traditional semiconductor, it's basically 12 to 13 weeks from when you start a wafer to when you get a product out the other end of the machine," McAfee explained. "The [3D V-Cache] stacking process adds time to that, and so it's longer than a quarter horizon [three months] to really ramp output of those products. And so we're working very, very hard to catch up with demand. I think as we go through the first half of this year, you'll see us continue to increase the output of X3D. There's no secret, X3D has become a far more important part of our CPU portfolio than I think any of us would have predicted a year ago. And I think that trend will continue in the future, and we are ramping capacity to ensure we catch up with that demand for as long as customers want those X3D parts."

McAfee said there isn't any particular component or part of the production flow creating the bottleneck.

"It's the problem that you've got that lead time to build individually the CCD wafer, the cache wafer, and then the stacking process that follows that, which also adds a considerable amount of time. It's a non-trivial timeline when you're talking about building X3D products."

佢哋啲cpu燒撚曬未?

佢哋啲cpu燒撚曬未?